Production Part Approval Process (PPAP) - Quality-One

What is Production Part Approval Process (PPAP) PPAP defines the approval process for new or revised parts, or parts produced from new or significantly revised production methods.

Production Part Approval Process Training - Quality-One

The PPAP Online Overview is perfect for a basic introduction to PPAP or for a subject matter review. The online course is self-paced and provides immediate access to PPAP content and is available 24 …

Quality Core Tools | Quality-One

Production Part Approval Process (PPAP) is a standardized process in the automotive and aerospace industries. PPAP demonstrates through documentation that as manufactured, the product and …

APQP | Advanced Product Quality Planning | Quality-One

Product Part Approval Process (PPAP) highlights the proof or evidence collected through APQP. Validated results from the first trial run supports the assertion that quality of delivery is expected.

Control Plan Development - Quality-One

Control Plans are currently being utilized to ensure product quality in the Automotive, Aerospace, Agricultural Equipment, Heavy Equipment and many other industries throughout the world. A Control …

Production Part Approval Process Support - Quality-One

PPAP Support will help you succeed by facilitating the PPAP process, directing activities for each PPAP element and completing PPAP submissions on time.

Process Failure Mode & Effects Analysis - Quality-One

Mitigation of the identified risk prior to first article or Production Part Approval Process (PPAP) will validate the expectation of superior process performance.

Suppliers shall retain a master sample as defined in the AIAG PPAP standard or provide approved controlled waiver. NOTE: Generally due to the volume and size of Organization parts we may not …

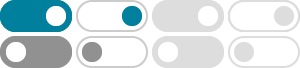

= The supplier shall submit to the customer and retain a copy of records or documentation items at appropriate

Measurement System Analysis (MSA) - Quality-One

It may be required for a PPAP submission to the customer. Furthermore, if any issues should arise, a new study can be performed on the gage and the results compared to the previous data to determine …